@GAIA – Apr. 2011 – O. Baverel, L. Boulais

An awareness to composite materials is proposed each year by the Architecture School of Grenoble to encourage new applications in the construction domain. Three objects are generally realised during the workshop. The first one, made of thermoformable plastic, proposes an investigation of shading systems, the second a focus on sandwich panel construction and the third a realisation of an elastic gridshell made of pultruded members. This year, sandwich panels are used to build a shelter using a reciprocal system or plated nexorade.

Objectives:

Within the framework of the Constructive Cultures Master program of the Ecole Nationale Supérieure d’Architecture de Grenoble, an awareness to composites materials is proposed each year to encourage new applications in the construction domain. This initiation addresses two composite manufacturing processes:

- Thermoforming for which the base material is here the Corian® (Dupont de Nemours). The use of this new material in architecture is today limited to bathrooms or kitchens, but still presents very interesting properties for the development of new applications.

- Thermosetting for which the base materials are here glass fibers and polyester. The implementation of these materials and their combination lead a better understanding of the whole process (preparation of the form, making of molds and oddside molds…).

Realisations:

Three objects are realised during the workshop. The first group works with Corian®. This material is very easy to machine and allows for a wide variety of forms and assemblies, including bending and cambering… Different combinations are investigated for shading systems based on three-dimensional arrangements, like overlapping, ribbings, hanging… all of which are used to understand the fundamental properties of composites.

The second one focuses on sandwich panel construction. The well-known principle of these panels is to optimize the use of material by setting it where useful, i.e. on the outer layers. This year, small panels have been made and assembled in a multi-reciprocal way to form a plated nexorade. The final object is an original shelter with almost no connection, but just interlocking members.

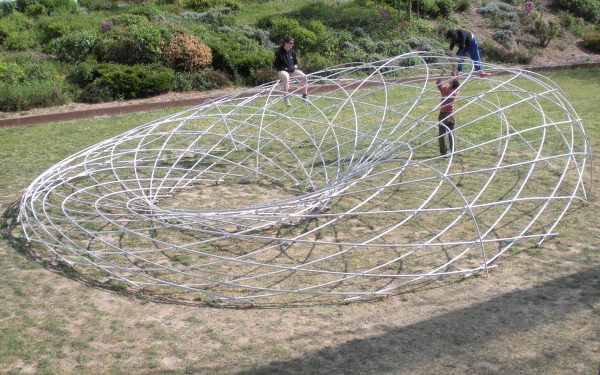

The third one studies an elastic gridshell made of pultruded members. A structure using a non-standard mesh is achieved by progressive assembling of the members (whereas the standard way of building will be to assemble first the whole grid on the floor before deforming it). This non-standard mesh gives a higher freedom for shape generation and allowed here to build a tunnel like gridshell.

Shading system

Plated nexorade

[flickr_set id=”72157654533586113″ max_num_photos=”4″]