@ENPC – Sept. 2019 – X. Tellier

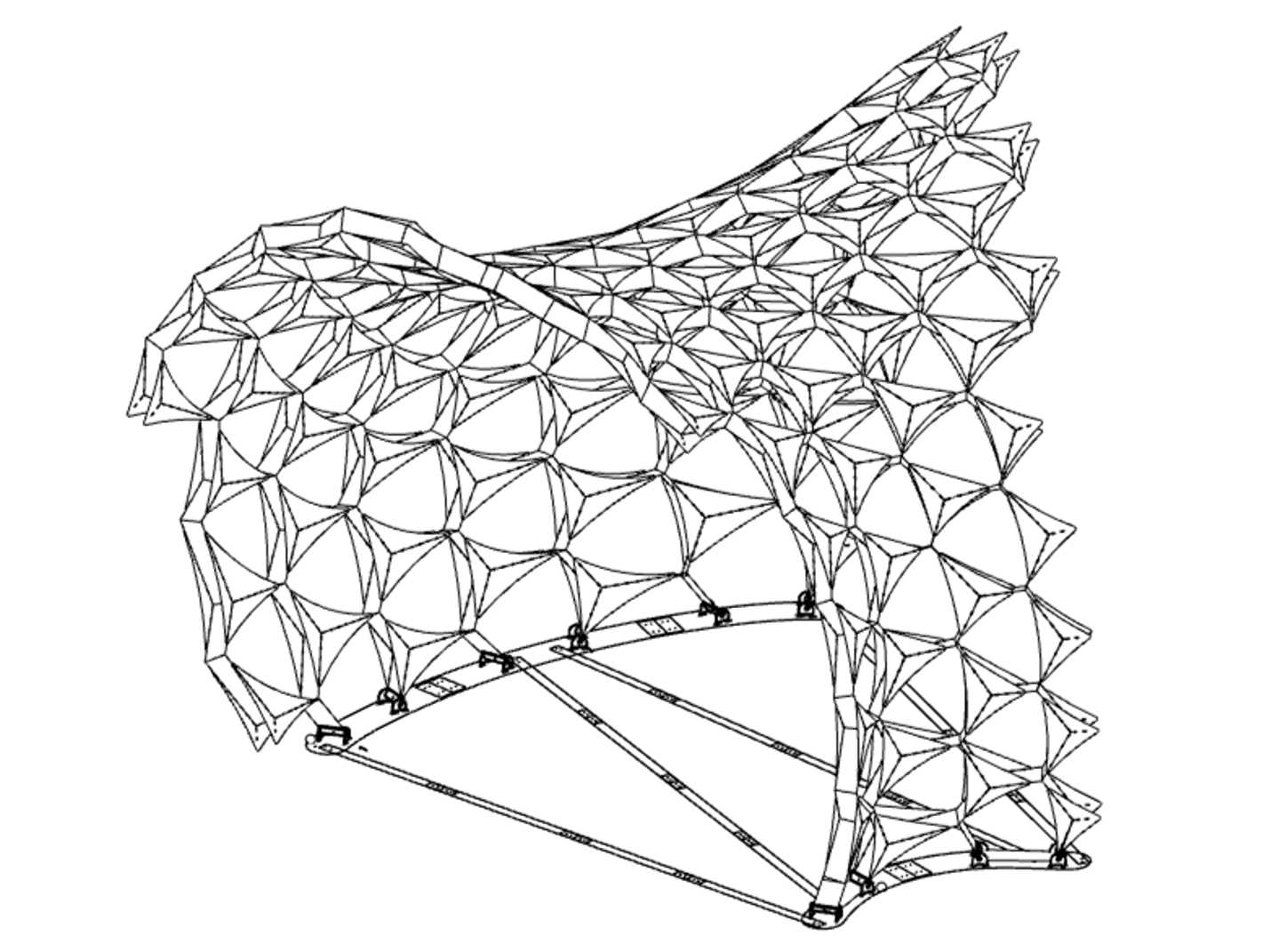

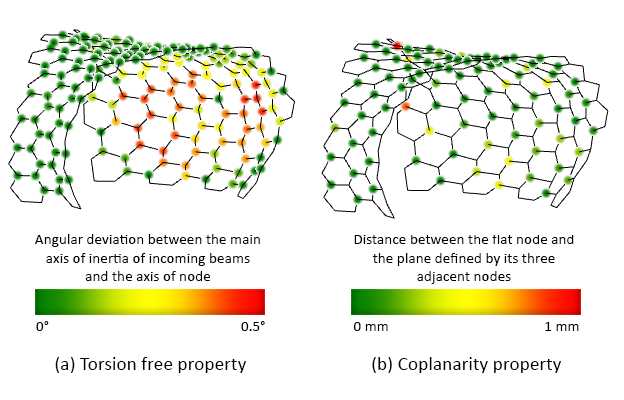

The fabrication of a freeform structural envelope is usually a highly complex task. The costliest aspect is often the connections between the constitutive parts. The Caravel heX-Mesh Pavilion is a prototype that demonstrates a new rationalization strategy. Its structure, composed of a hexagonal grid of beams and cladding panels, is based on a geometry that rationalizes connections at two levels: firstly, nodes are free of geometrical torsion and are repetitive: only two types of nodes are used. Secondly, panels can easily be connected to the support beams as they are orthogonal to each other. The mechanical behavior is validated by finite-element analysis. We generate these meshes by numerical optimization from a smooth target surface, with an initialization derived from the asymptotic case and surface theory. The pavilion shows an alternative way of rationalizing a gridshell beyond the popular planar-quad meshes and circular/conical meshes. It also demonstrates a way to generate hexagonal gridshells which are not necessarily synclastic, this limitation being typically imposed to achieve planarity of cladding panels.

Facts and figures

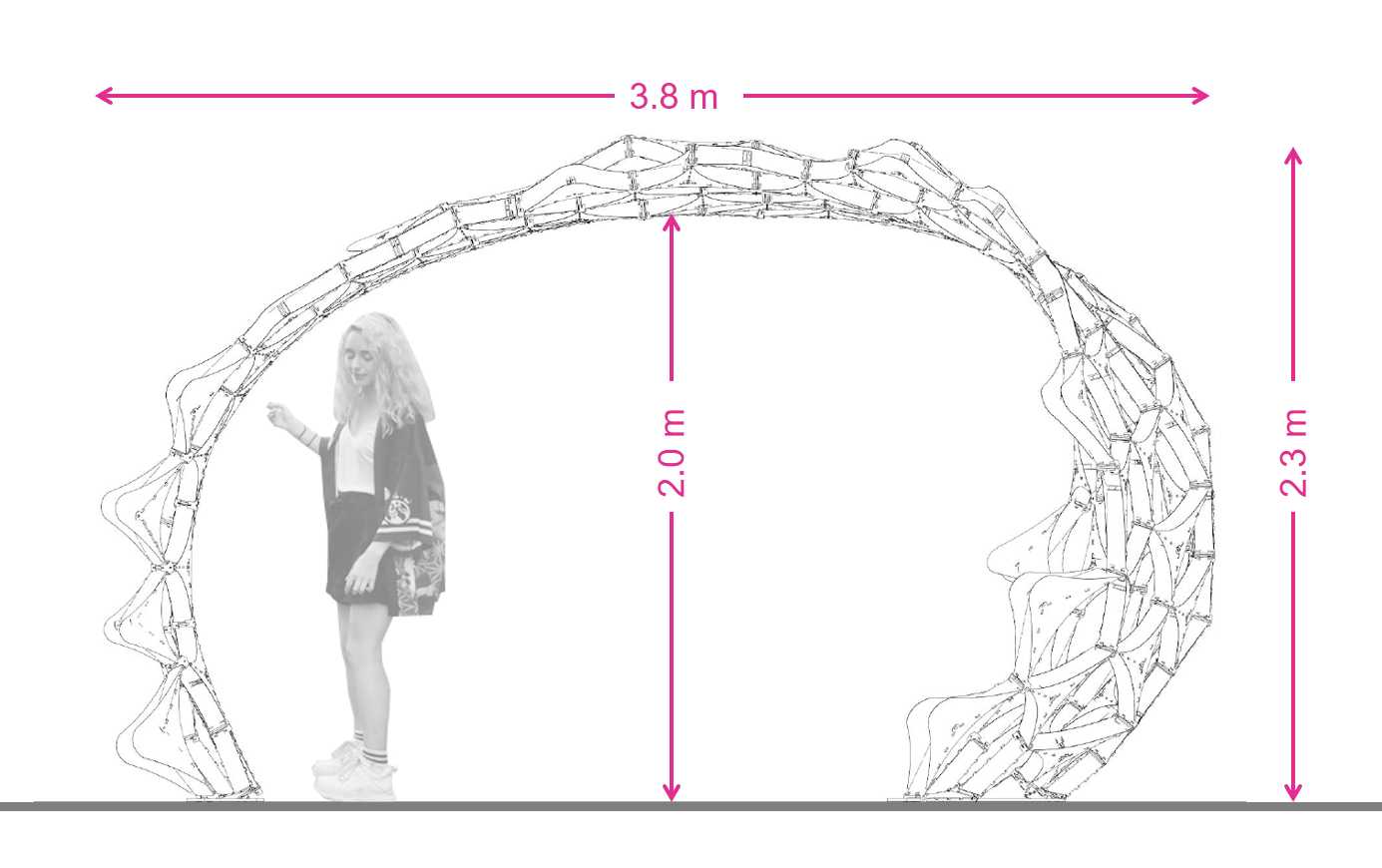

- Dimension: 3.25m span x 4m long x 2.7m high

- Panel Material: 1.5 galvanised steel plates

- Beam & supports material: 4mm painted steel

- Total Weight of Prototype: 192kgs

- Assembly Time: 8 hours x 6 people

- PhD Student: Xavier TELLIER

- Arch. students: Sonia ZERHOUNI, Guillaume JAMI, Alexandre LE PAVEC, Thibault LENART, Mathieu LEROUGE a,

- Advisors: Nicolas LEDUC, Cyril DOUTHE, Laurent HAUSWIRTH, Olivier BAVEREL

- Academic partners: ENSAPM, ENPC, Navier, LAMA

- Industrial partners: Viry (Fayat group)

Description of design strategy

The starting point of the design is a horseshoe arch surface, chosen for its aesthetic and its functionality relatively to the implantation site at the IASS exhibition 2019. Such shape cannot be funicular. It therefore highlights the potential of the proposed constructive system to resist bending. Bending stiffness and resistance is allowed by the structural depth of the structure. Usually, structural depth in gridshells amplifies fabrication issues due to geometrical torsion at nodes. This is not the case with Caravel meshes thanks to their torsion-free nodes.

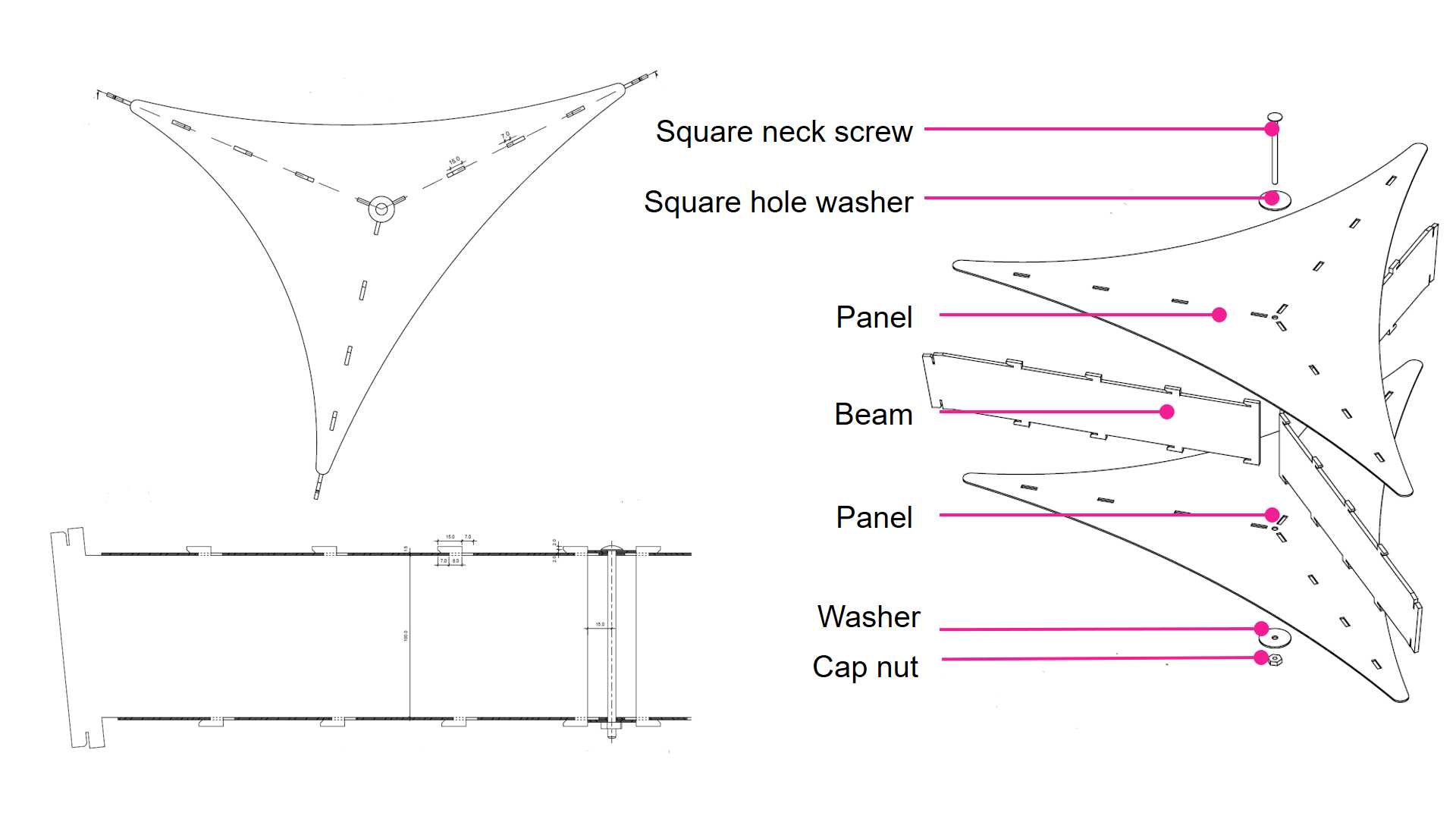

This surface was discretized by a hexagonal mesh aligned with curvature lines. There are two ways to align a hexagonal mesh with curvature directions. The alignment with the horizontal curvature lines is chosen in order to create the graphic impression of an ascending movement, as the triangular panels are pointing upwards diagonally.

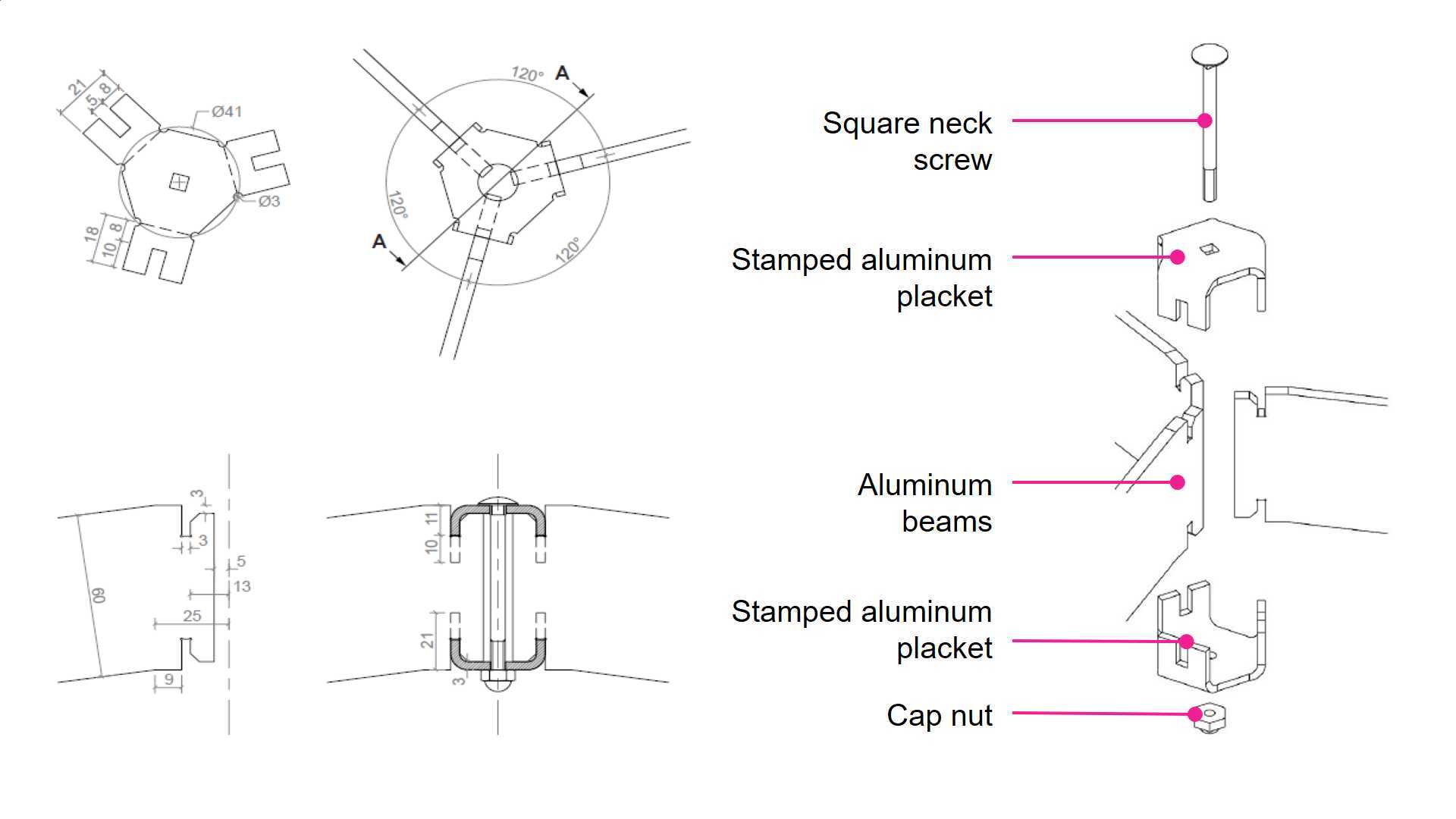

The concept of this pavilion focuses on highlighting the geometrical properties through the architectural treatment of the elements, especially the connections. The conception of each type of node is entirely based on the geometrical rationalization that simplifies its fabrication, and takes advantage of each geometrical strategy to define its technology.

Detailing

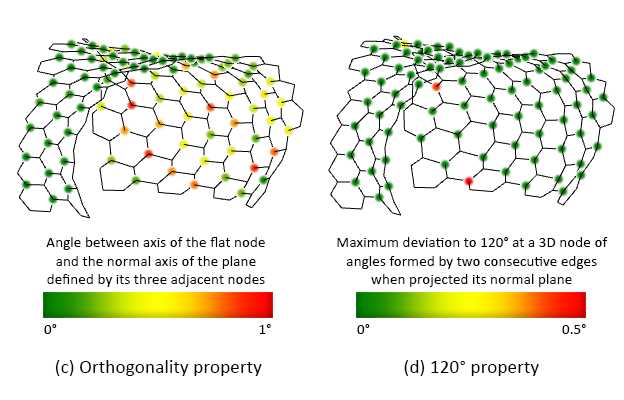

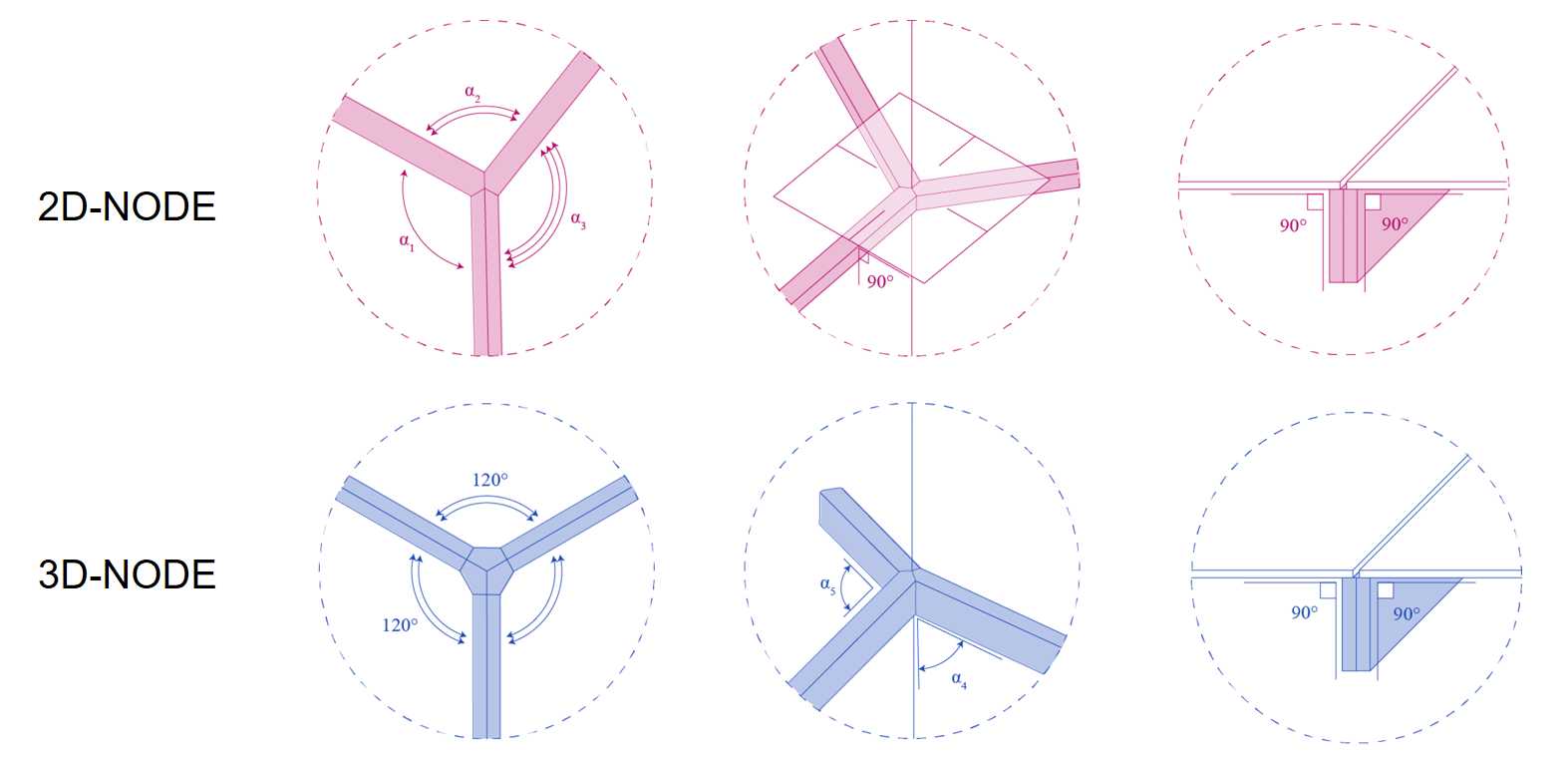

The proposed geometrical configuration is a continuation of the work presented in Tellier 2019. The configuration is based on a hexagonal mesh with non-planar faces. Each of its nodes is assigned with an axis. The configuration satisfies the following properties:

- The axes of two adjacent nodes are coplanar and their common plane corresponds to the median plane of the beam;

- Every other node is flat: the incoming edges are coplanar. These nodes are referred to as 2D nodes, the other nodes are named 3D nodes;

- For 2D nodes, the axis is perpendicular to the plane of the node;

- For 3D nodes, the beam planes intersect at 120°.

Relevant references

Tellier, X., C. Douthe, L. Hauswirth, and O. Baverel (2020, September). Caravel meshes: A new geometrical strategy to rationalize curved envelopes. Structures 28, 1210–1228.

Tellier, X., S. Zerhouni, G. Jami, A. Le Pavec, T. Lenart, M. Lerouge, N. Leduc, C. Douthe, L. Hauswirth, and O. Baverel (2020, April). The Caravel heX-Mesh pavilion, illustration of a new strategy for gridshell rationalization. SN Applied Sciences 2(4).