@ENPC – March 2014 – C. Douthe, M.Vrontissi

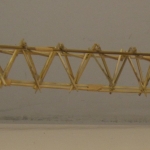

From design to fabrication in one week. This yearly workshop mixes third year engineering and architecture students. It starts with an introduction to structural mechanics and to bridge design and it ends up with the construction of a 6m footbridge. Students not only get familiar with all the steps of the design process but make the physical experiment with their own body of the full scale realisation of an object that they have conceived. A first experience as builders that most of them will remember.

Detailed constraints

Each group of students has to design and build a bridge over a gap of 7m, which means: not a sculpture but a structure capable of supporting the crossing of a member of the team. The gap is delimited by two main supports consisting of tables with a height of about 0.75m. Between these two supports, the structure can have as many intermediate supports as necessary to the extent that a clearance of 2.8m² is left free below the structure. The minimum width of the deck available for users is 0.50 m. There are no special requirements for the slope of the bridge as long as the crossing of the 7m remains possible and as the deck remains below 1.30m.

For obvious safety reasons, the supervisors and the jury are the only ones able to allow the crossing of the bridge and reserve the right to do pre-loading tests, so that each bridge must be able to withstand a load of 100kg placed in any point. To support the different loads, it is permitted to use some team members to weight the abutments, which must be managed accordingly.

Teaching Material

Material at one’s disposal

- 120m of wood (25x27mm)

- 50m of sisal rope

- 500 screws

- 2m² of 5mm plywood

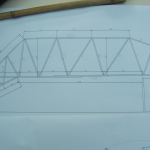

Features of the 2014 edition

The novelty of this 2014 edition was the introduction of templates for the renderings. This deeper formalisation had three objectives:

- to precise the typical level of details at each design stage,

- to improve the quality of connections

- to improve the general efficiency of the construction method.

And it worked! By increasing the hours dedicated to studies and construction survey, a lot of hours were saved during construction and improvisations on the field were pretty much reduced. And in totality, the number of working hours of the workshop was reduced to about 3-4 hours per person.